Home >Products >Automotive Mold >auto radiator fan mold maker

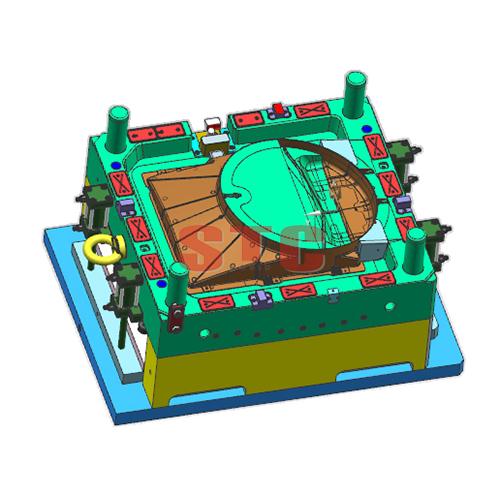

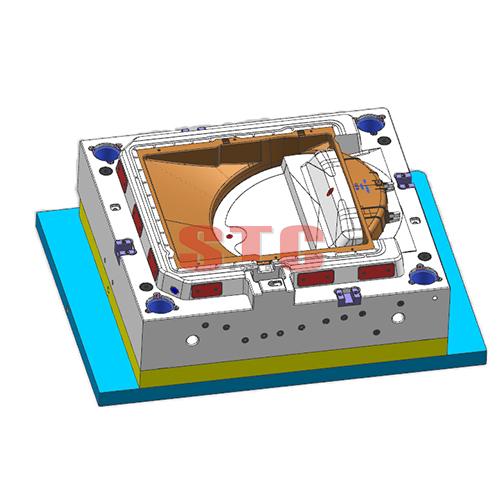

auto radiator fan mold maker

- Product Item : STC-10

- Category:Automotive Mold

- Views:598

- Product description:auto radiator fan mold in china, industrial fan part mold

PRODUCT DESCRIPTION:

Mould cavity number: single cavity, cavity, or according to customer's requirement

Product material : PP-GF30 PA66-GF30

Product material : PP-GF30 PA66-GF30

Die steel, 45 #, P20H, 718 h, NAK80, 2738, H13, S136, or according to customer's requirement

The mold cavity, a cavity or multi-cavity

The mold hardness: 35-55 HRC According to the material

Runner system: cold runner and hot runner

Cooling system: optimal design of circulating water, improve the production efficiency, reduce the cost of you

Die set materials: LAM, FUTABA, DME, HASCO or according to customer specified

Surface treatment: corrosion, mirror processing, grinding surface, prints, or according to customer specified surface

Mould standard: LKM, DME, dish, or according to the customer

Die life: 100000-1 million according to customer's materials

Manufacturing cycle: 2-8 weeks, on the basis of mold on the difficulty level

The main process: milling, grinding, CNC, EDM, wire cutting, carved, EDM, etc

Processing capacity: mold design, mold manufacturing and injection molding processing, assembly, screen printing, etc

Design software: CAD, Pro - E, UG, etc

Design time: 3 days (in general)

The mode of transportation: before the mould shipment must be put locked mold piece, wrap film packaging, then packed in wooden case. Strong packing, rust, logistics transport.

The early stage of the mould: 3 d review, product Moldflow analysis, to determine the best design scheme, design of mould structure, customer confirmed

Mould process: plan approval - material - processing - die set processing, mold core processing, electrode processing, mold parts processing, inspection, assembly, test mode, try to send sample, customer feedback, cooling water - packing shipment

If appearance product first time customers are not satisfied, we will change according to customer requirements, until is like a customer to confirm qualified.

>Mould Name:Auto Radiator Fan mold

>Product Size:634*806*154mm

>Product Description:Auto radiator Fan mold

>Mould Cavity:1 cavity

>Mould Size:940*1310*840mm

>Suitable Machine:1250T injection machine

>Mould Main Material:P20H

>Mould Injection System:2 Hot tips Hasco hot runner

>Mould Ejection System:Mechanical ejector by injection machine

>Mould Cycle Time:120 seconds / shot

>Delivery Time:55 days

>Mould features: One-stop solution from design to mould manufacture and mass production

PREVIOUS:Auto engineer part moldNEXT:Griller injection mold

Products Category

LATEST NEWS

CONTACT US

Name: susan zhao

Mobile:0086-13757668082/13666869224

Tel:0086-576-84036082

Email:Mold@stc-plasticmold.com

Add:16# Jinniu Road North of Huangyan Taizhou Zhejiang China

susan zhao

susan zhao susan zhao

susan zhao